The year 2025 has brought significant changes to cargo container specifications, driven by updated international shipping regulations, sustainability targets, and advances in logistics technology. Whether you are exporting goods to distant markets or importing bulk shipments, understanding the latest container standards is essential for avoiding delays, reducing costs, and ensuring compliance.

1. Why Cargo Container Specifications Matter in 2025

Standardized container specifications enable smooth transitions between ships, trucks, and rail. In 2025, higher cargo volumes and tighter regulations make it critical for shippers to select the right container type and comply with new safety and environmental requirements.

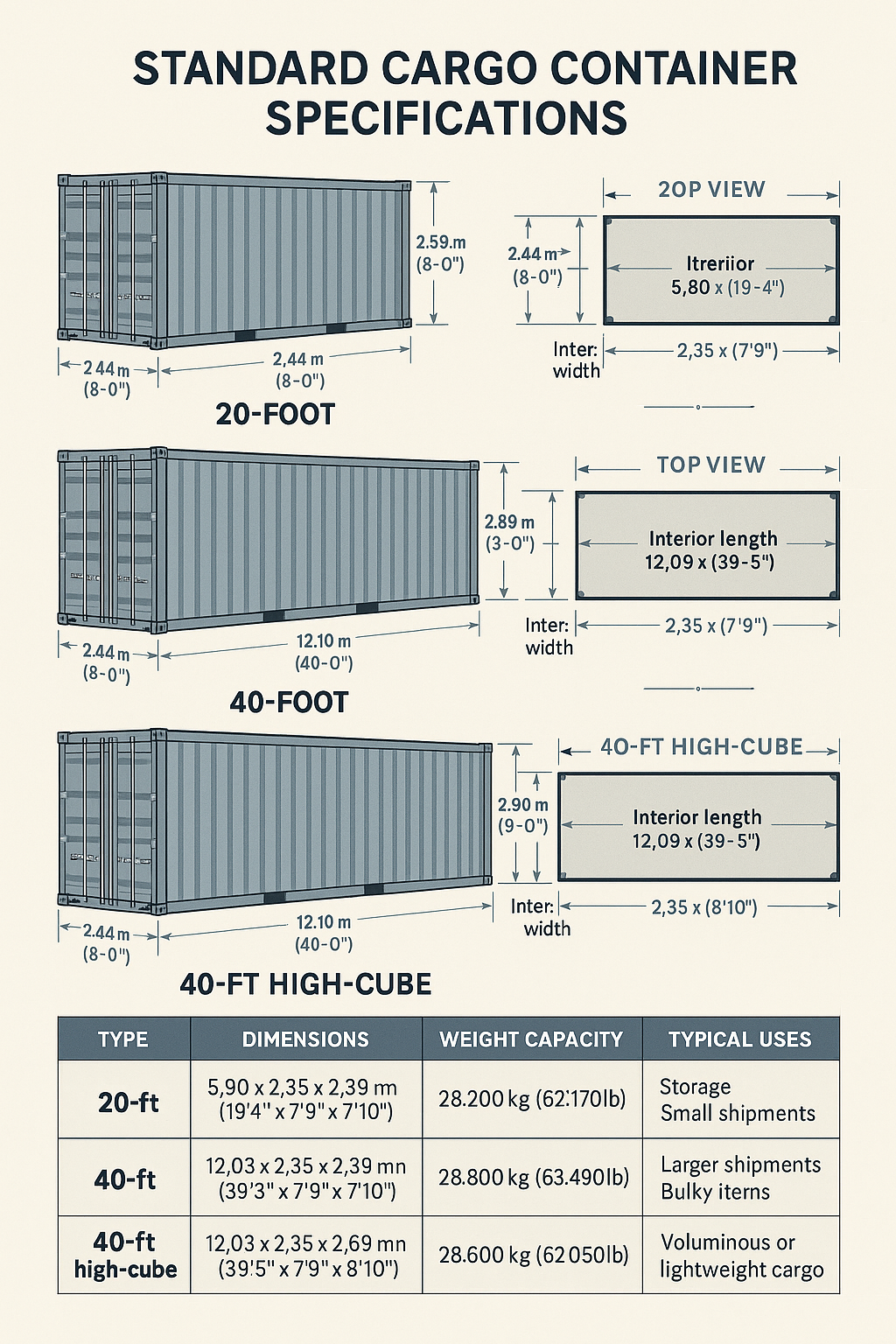

2. Standard Container Sizes and Dimensions

The following ISO-compliant cargo container specifications remain the industry benchmark in 2025:

| Container Type | External Length | External Width | External Height | Internal Volume | Max Gross Weight | Common Use |

|---|---|---|---|---|---|---|

| 20ft Standard | 6.06 m (19’10”) | 2.44 m (8’) | 2.59 m (8’6”) | 33.2 m³ | 24,000 kg | General cargo |

| 40ft Standard | 12.19 m (40’) | 2.44 m (8’) | 2.59 m (8’6”) | 67.7 m³ | 30,480 kg | Bulk cargo |

| 40ft High Cube | 12.19 m (40’) | 2.44 m (8’) | 2.90 m (9’6”) | 76.4 m³ | 30,480 kg | Light, bulky goods |

| Reefer Container | Varies | 2.44 m (8’) | 2.59 m (8’6”) | Varies | 29,000 kg | Perishables |

3. Shipping Times and Conditions in 2025

Transit times depend on the route, port congestion, and carrier service type:

| Route | Sea Freight Transit Time | Common Conditions | Typical Incoterms |

|---|---|---|---|

| China – US West Coast | 14–18 days | CY–CY; possible congestion delays | FOB, CIF |

| China – US East Coast | 25–30 days | Panama Canal transit; weather delays possible | CFR, DDP |

| China – Europe (Rotterdam) | 30–35 days | Peak season surcharges may apply | FOB, CIF |

| China – Australia (Sydney) | 12–15 days | Biosecurity inspections required | FCA, DAP |

4. Key 2025 Updates to Cargo Container Specifications

| Update Type | New Requirement | Impact on Shippers |

|---|---|---|

| Safety Certification | CSC plate now includes QR code for digital verification | Faster port checks, reduced delays |

| Eco-Friendly Materials | Higher proportion of recycled steel in construction | Meets green shipping policies, potential subsidies |

| Smart Monitoring | Integrated weight sensors | Prevents overloading fines, improves cargo safety |

| Structural Strength | Reinforced corner posts for higher stacking | Enables larger vessel capacity |

5. How to Choose the Right Container

When selecting a container:

- Identify Cargo Type – dry goods, reefer, hazardous, oversized.

- Calculate Volume & Weight – avoid paying for unused space or exceeding payload.

- Check Destination Rules – some ports restrict high cube or reefer entry.

- Consider Handling Method – forklift, crane, or manual loading.

💡 Example:

- Lightweight goods → High cube for more volume

- Dense, heavy goods → 20ft container for safety

- Get expert advice and competitive rates tailored to your cargo container specifications. Contact our logistics team today.

6. Tips to Avoid Shipping Delays

| Risk Factor | Prevention | Result |

|---|---|---|

| Peak Season Space Shortages | Book 4–6 weeks ahead | Avoid premium rates |

| Damaged Container | Inspect before loading | Prevent rejection at destination |

| Documentation Errors | Double-check B/L details | Avoid customs clearance delays |

| Customs Inspection | Prepare all certificates in advance | Shorter port dwell times |

7. Regulatory Compliance and Safety Checks

In 2025, cargo container specifications must meet stricter compliance rules:

- ISO 668 & ISO 1496: Standardized dimensions and strength.

- CSC Rules: Structural safety inspection every 30 months.

- IMDG Code: Specific requirements for dangerous goods transport.

- Country-Specific Laws: e.g., mandatory fumigation in Australia, pest control in Japan.

📌 Note: Violations can result in cargo rejection, fines, or destruction.

8. Container Maintenance and Inspection

Good maintenance ensures container longevity and prevents cargo damage:

Key Inspection Points:

- Flooring – No cracks, rot, or water damage.

- Locking Rods – Well-lubricated and corrosion-free.

- Rubber Seals – No aging or detachment.

- Corner Castings – Intact for stacking safety.

- 🔍 Tip: Take photos when renting to document condition.

9. Cost Factors Related to Cargo Container Specifications

| Cost Factor | Description | Savings Strategy |

|---|---|---|

| Size Selection | High cube vs standard | Match to cargo volume |

| Special Containers | Reefer, tank, open-top | Consolidate shipments |

| Oversized Cargo | Requires permits and special handling | Declare early, plan route |

10. Future Container Design Trends

- Smart Features: GPS, temperature, and humidity monitoring.

- Modular Interiors: Adjustable partitions for mixed loads.

- Lightweight Materials: Reduced tare weight for fuel savings.

- Automation-Ready: Compatible with robotic handling systems.

11. 2024 vs 2025 Cargo Container Specifications

2025 updates reflect sustainability policies, digital safety verification, and mega-vessel adaptability.

| Comparison Item | 2024 Specification | 2025 Specification | Impact |

|---|---|---|---|

| CSC Plate | Traditional metal tag, manual check | QR code for digital scan | Faster verification |

| Material | Mostly new steel | Higher recycled steel ratio | Eco-compliance, subsidies |

| Smart Features | GPS in premium units only | GPS & weight sensors standard in mid/high-tier | Enhanced tracking |

| Stacking Strength | Standard ISO rating | Stronger corner posts for mega ships | Higher stacking efficiency |

| Inspection Frequency | 30-month CSC cycle | Added spot checks on high-risk routes | Extra inspection time needed |

| High Cube Share | ~35% market | ~42% market | More volume for light goods |

Recommendations:

- Exporters: Verify digital CSC compliance before booking.

- Importers: Ensure high cube containers meet destination height rules.

- Freight Forwarders: Offer smart container tracking as a value-added service.

12.Conclusion

In 2025, mastering cargo container specifications is key to faster, safer, and more cost-effective shipping. The right container choice, paired with compliance and smart planning, keeps your cargo moving smoothly and your bottom line strong.

Request a Quote

Need a tailored solution for your shipping from China?

Let TJ China Freight Forwarder assist you with reliable, cost-effective service.

FAQ:

Q1.Can I brand the exterior of my container?

Yes, provided modifications don’t compromise structural safety or CSC certification.

Q2.What is the average service life of a container?

About 12–15 years in active use, longer if maintained.

Q3.Are reefers stackable like dry containers?

Yes, but airflow gaps must be left for cooling.

Q4.How do I confirm ISO compliance?

Check the CSC plate and manufacturer’s certificate.

Q5.Can I insure the container separately from cargo?

Yes, container insurance covers physical damage or loss.