Logistics containers are the backbone of international freight movement, ensuring goods are transported securely, efficiently, and in compliance with global shipping standards. Whether shipping electronics, furniture, machinery, or perishables, the right container type can reduce costs, minimize damage risks, and speed up delivery.

1. Understanding Logistics Containers

Logistics containers are standardized metal boxes used in sea, rail, and intermodal transport. They are designed for durability, security, and easy handling. The most common materials are steel and aluminum, with standardized sizes set by ISO (International Organization for Standardization).

Main benefits include:

- Protection from weather and theft

- Efficient stacking and handling at ports

- Compatibility with various transport modes

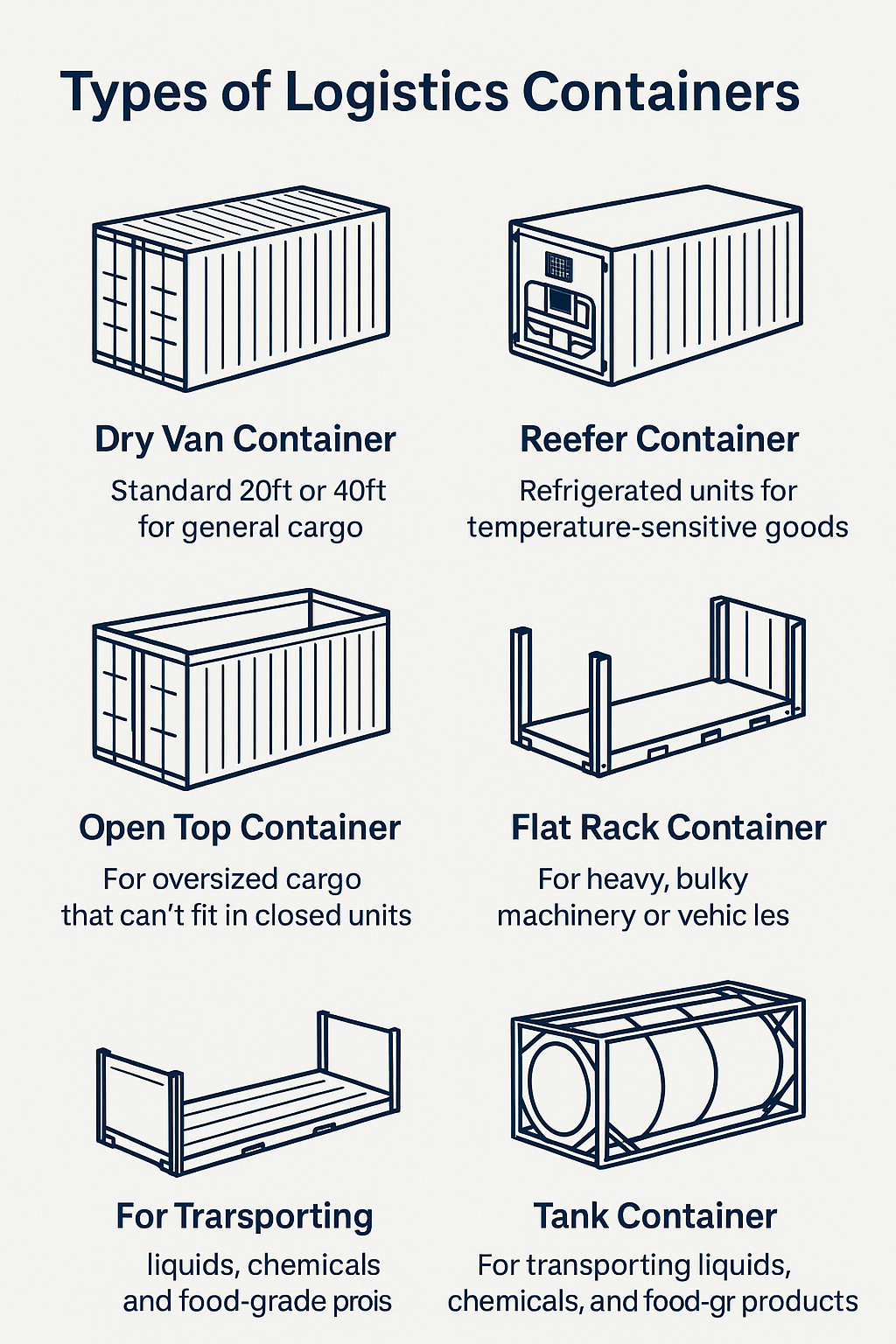

2. Common Types of Logistics Containers

Different cargo types require different containers. Below are the most widely used:

- Dry Van Containers – Standard 20ft or 40ft for general cargo.

- Reefer Containers – Refrigerated units for temperature-sensitive goods.

- Open Top Containers – For oversized cargo that can’t fit in closed units.

- Flat Rack Containers – For heavy, bulky machinery or vehicles.

- Tank Containers – For transporting liquids, chemicals, and food-grade products.

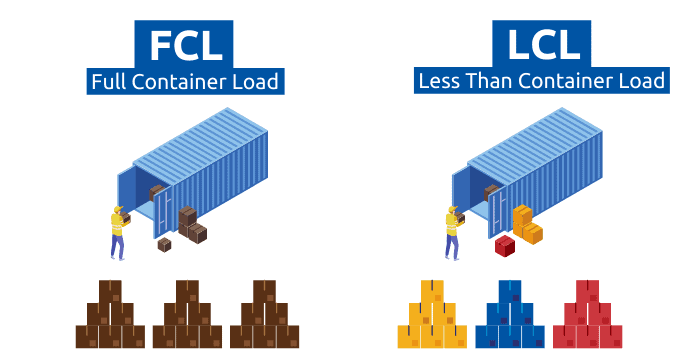

3. FCL vs LCL in Logistics Containers

- You book an entire container for your cargo.

- Best for large shipments and maximum security.

📍LCL (Less than Container Load)

- You share container space with other shippers.

- Cost-effective for smaller volumes but may take longer due to consolidation.

4. Shipping Time, Conditions & Terms (Comparison Table)

| Container Type | Typical Shipping Time (China to Europe) | Typical Conditions | Common Terms |

|---|---|---|---|

| 20ft Dry Van | 28–35 days | General cargo, dry goods | FOB, CIF |

| 40ft High Cube | 28–35 days | High-volume shipments | CFR, DDP |

| Reefer Container | 28–32 days | Temp-controlled goods | CPT, CIP |

| Open Top Container | 30–36 days | Oversized cargo | EXW, FCA |

| Flat Rack Container | 30–36 days | Heavy machinery | FAS, CFR |

| Tank Container | 28–34 days | Liquids/chemicals | CFR, DAP |

5. How to Choose the Right Logistics Container

Selecting the correct logistics containers involves balancing cargo needs, cost efficiency, and operational practicality. Here’s a step-by-step approach:

1⃣️ Identify Cargo Characteristics

- Dry, perishable, hazardous, or oversized?

- Example: Fresh seafood → Reefer container; Excavator → Flat rack container.

2⃣️ Determine Load Volume & Weight

- Use 20ft for heavy cargo with lower volume.

- Use 40ft for lighter, high-volume goods.

3⃣️Match to Route & Weather

- Long voyages through extreme climates may need enhanced insulation or weatherproofing.

4⃣️ Consider Handling Equipment

- Ports with limited equipment may not handle certain special containers.

6. Key Cost Factors in Container Shipping

When budgeting for logistics containers, consider these four main cost drivers:

| Cost Factor | Description | Impact on Price |

|---|---|---|

| Container Type & Size | Specialized reefers or flat racks cost more than standard dry vans | High |

| Route & Distance | Remote or low-traffic routes increase transport cost | Medium–High |

| Seasonal Demand | Rates spike during holiday shipping seasons | Medium |

| Port & Customs Charges | Loading, unloading, inspection, and clearance fees | Medium |

📌Tip: Book early in peak seasons to lock in better rates.

7. Compliance & Documentation

Using the right logistics containers also means meeting all legal and safety rules.

Mandatory checks include:

- Customs paperwork – Bill of Lading, commercial invoice, and packing list.

- Cargo restrictions – Certain hazardous goods require permits and IMO labeling.

- Container certification – Must comply with CSC (Container Safety Convention) and ISO standards.

Failure to comply may cause delays, fines, or even shipment rejection.

8. Best Practices for Optimizing Container Use

Maximize efficiency and reduce risk by following these practices:

- Full Utilization – Avoid shipping half-empty containers; consolidate where possible.

- Proper Packing – Use pallets, dunnage, and moisture protection for long voyages.

- Digital Tracking – GPS-enabled containers improve security and route efficiency.

- Seasonal Planning – Ship during off-peak months to reduce congestion and cost.

- Work with Reliable Forwarders – They help navigate customs and handle port operations smoothly.

9. Environmental Impact of Logistics Containers

Modern logistics containers are being designed for sustainable shipping:

- Reusable and recyclable materials.

- Energy-efficient reefers with low-carbon cooling systems.

- Digital tracking to optimize routes and reduce emissions.

10. Conclusion

Choosing the right logistics containers can make a significant difference in cost, speed, and cargo safety. By understanding container types, terms, and best practices, shippers can maximize efficiency and minimize risks in global trade.

Request a Quote

Need a tailored solution for your shipping from China?

Let TJ China Freight Forwarder assist you with reliable, cost-effective service.

FAQ:

Q1.What is the lifespan of a standard logistics container?

Typically 10–15 years, depending on usage and maintenance.

Q2.Can I modify a logistics container for storage purposes?

Yes, but it must be decommissioned from shipping service first.

Q3.Do logistics containers have GPS tracking?

Some high-value shipments use GPS-enabled containers for real-time tracking.

Q4.How are containers cleaned between shipments?

They undergo professional cleaning, fumigation, or sanitization depending on cargo type.

Q5.Are there size limitations for logistics containers?

Standard sizes are 20ft and 40ft, but specialized containers vary in height and width.